Compared with traditional concrete buildings, steel structure buildings use steel plates or section steel to replace reinforced concrete, which is stronger and more resistant to earthquakes. And because the component can be factory made, site installation, thus greatly reducing the construction period. Due to the reusable steel, it can be greatly reduced the construction waste, and more green environmental protection, so it is widely used in industrial buildings and civil buildings over the world.

Items | Specifications | |

Main Steel Frame | Column | Q235B, Q355B Welded H Section Steel |

Beam | Q235B, Q355B Welded H Section Steel | |

Secondary Frame | Purlin | Q235B C and Z Purlin |

Knee Brace | Q235B Angle Steel | |

Tie Rod | Q235B Circular Steel Pipe | |

Brace | Q235B Round Bar | |

Vertical & Horizontal support | Q235B Angle Steel, Round Bar, or Steel Pipe | |

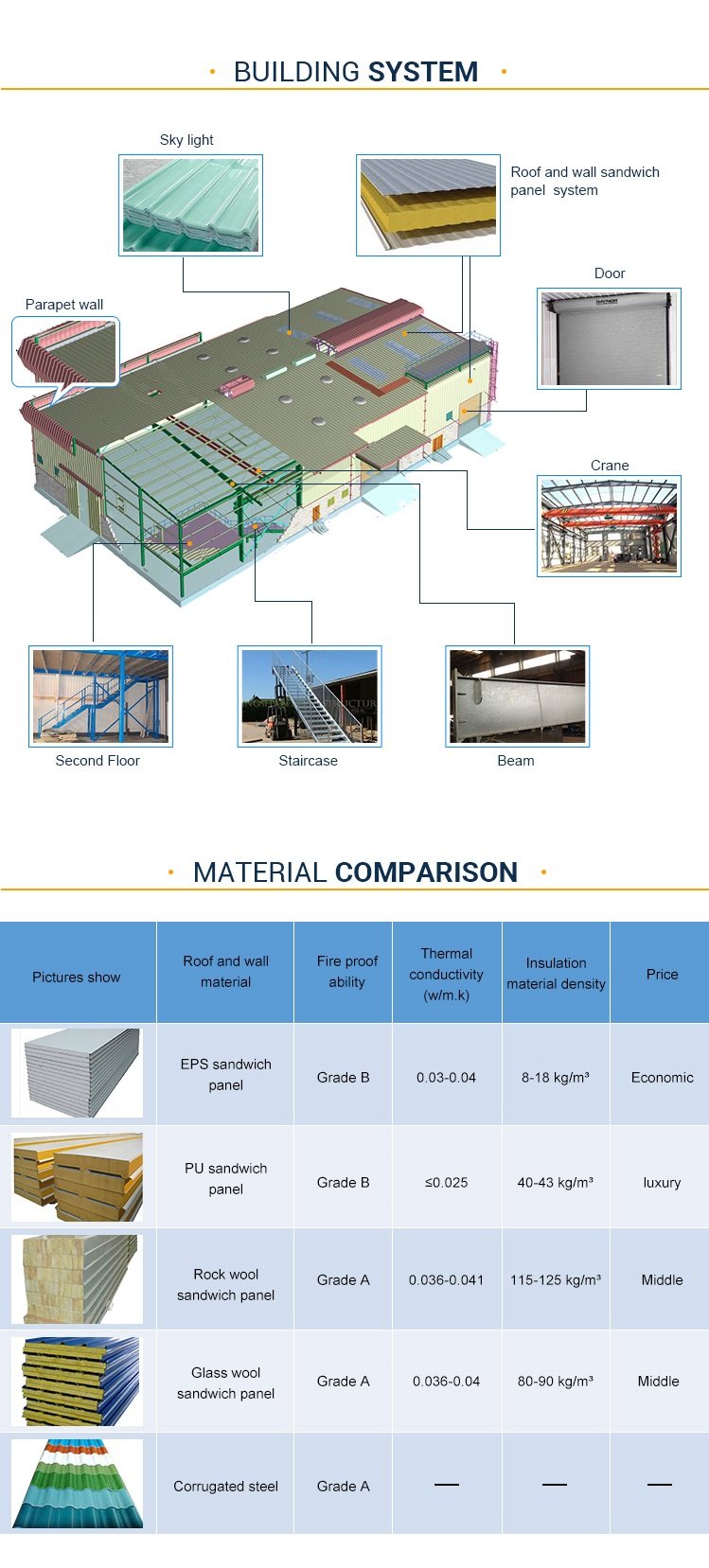

Maintenance System | Roof Panel | EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet |

Wall Panel | EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet | |

Accessories | Window | Aluminum Window, Plastic Steel Window |

Door | Aluminum Door, Rolling Metal Door | |

Rainspout | PVC | |

Fastener | High Strength Bolts, Normal Bolts, Chemical Bolts | |

Ventilation System | Natural Ventilator, Ventilation Shutters | |

Live Load on Roof | In 120kg Sqm (Color steel panel surrounded) | |

Wind Resistance Grade | 12 Grades | |

Earthquake-Resistance | 8 Grades | |

Structure Usage | Up to 50 years | |

Temperature | Suitable temperature -50°C~+50°C | |

Certification | CE, SGS,ISO9001:2008,ISO14001:2004 | |

Finishing Options | Vast array of colors and textures available | |

Low Cost Construction Design Steel Metal Structure Building Plans Price Prefabricated Warehouse

A: Components of galvanized light steel structure

1)Wall panel: sandwich panel with color steel two sides and EPS foam filling width:1200mm 1k=1200

2)Column: C style steel, H shape

3)Floor beam: C style steel,200*40*2.0mm

4)Floor: light magnesium board (our patent)

5)Stair: metal

6)Roof truss: angle steel

7)Purling tube metal

8)Roof panel: corrugated sandwich panel with color steel two sides

9)Door: aluminum frame with panel same as wall, with lock

Remark: this list is for your reference but the elements can vary.

Technique Index

Earthquake resistante: 8 fission intensity

Wind pressure: <31m/s about 10 grade

Roofing snow load; <80kg/m2

Roofing live load: 50kg/m2

1. Economic : quick installed and saving the cost of construction

2. the period of delivery is very short and can installed very easily

3. Reliable quality: mainly produced in the factory and control the quality

4. big space: the max span of prefab steel structure can reach 80meters

5. antiseismic: because the weight is light

6. Flexible: can be dismantled and enlarged

7. Beautiful appearance: can use different colors

8. Long lifespan: can be used more than 30 years

B: The advantages of light steel structure

1)Economic : quick installed and saving the cost of construction

2)Reliable quality: mainly produced in the factory and control the quality

3)big space: the max span of prefab steel structure can reach 80meters

4)antiseismic: because the weight is light

5)Beautiful appearance: can use different colors

6)Long lifespan: can be used more than 50 years

C: If you need us to design the light steel building for you, we need to know the following:

1. rain load

2. live load

3.snow load

4.wind load

5.whether using the crane 6. length,wide,height

D :Features

Attractive design- -the whole house looks beautiful and elegant. The inner, outer walls and the roof boarding all use the color

steel sandwich panel, the material is polystyrene foam.

Light weight and convenient in shipping.

Easy to assemble and dismantle: the house can be rebuilt for dozens of times. The assembling only requires simple tools: plugs and

screw.

Firm structure- the house adopts steel frame structure ans sandwich panels.

Our houses are completely waterproof.

The house can be customized. The roof, wall, door, windows can be chosen by the customer.

Durable--the steel frame parts are all processed with anti-corrosion coating and can be used for as long as 20 years.

Quality check & control

Production Processing & Shipping