Compared with traditional concrete buildings, steel structure buildings use steel plates or section steel to replace reinforced concrete, which is stronger and more resistant to earthquakes. And because the component can be factory made, site installation, thus greatly reducing the construction period. Due to the reusable steel, it can be greatly reduced the construction waste, and more green environmental protection, so it is widely used in industrial buildings and civil buildings over the world.

Items | Specifications | |

Main Steel Frame | Column | Q235B, Q355B Welded H Section Steel |

Beam | Q235B, Q355B Welded H Section Steel | |

Secondary Frame | Purlin | Q235B C and Z Purlin |

Knee Brace | Q235B Angle Steel | |

Tie Rod | Q235B Circular Steel Pipe | |

Brace | Q235B Round Bar | |

Vertical & Horizontal support | Q235B Angle Steel, Round Bar, or Steel Pipe | |

Maintenance System | Roof Panel | EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet |

Wall Panel | EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet | |

Accessories | Window | Aluminum Window, Plastic Steel Window |

Door | Aluminum Door, Rolling Metal Door | |

Rainspout | PVC | |

Fastener | High Strength Bolts, Normal Bolts, Chemical Bolts | |

Ventilation System | Natural Ventilator, Ventilation Shutters | |

Live Load on Roof | In 120kg Sqm (Color steel panel surrounded) | |

Wind Resistance Grade | 12 Grades | |

Earthquake-Resistance | 8 Grades | |

Structure Usage | Up to 50 years | |

Temperature | Suitable temperature -50°C~+50°C | |

Certification | CE, SGS,ISO9001:2008,ISO14001:2004 | |

Finishing Options | Vast array of colors and textures available | |

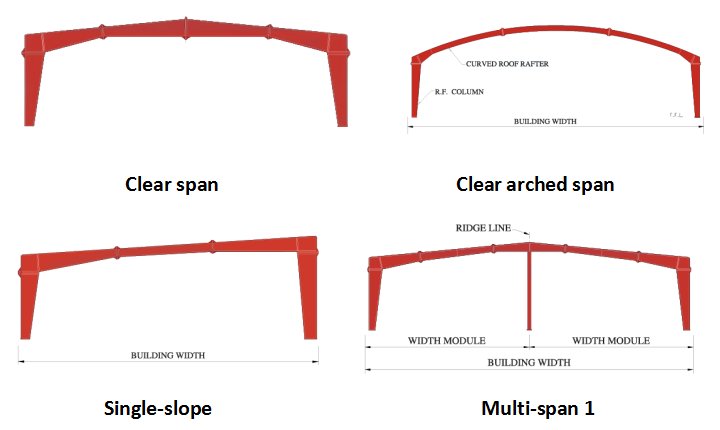

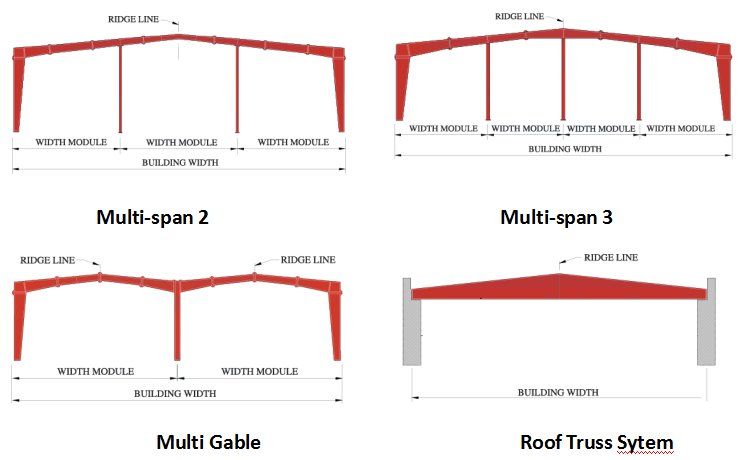

1. Primary Framing

Main steel frame is mainly composed of steel beams, steel columns, steel trusses and other components made of section steel and steel plate, and adopts rust removal and anti-rust process such as shot blasting, painting and galvanizing. Welding, bolts or rivets are usually used to connect each member or component. Our pre-engineered steel structure building is custom-designed to meet your exact requirements. The most common primary framing systems are shown below. Practically any frame geometry is possible.

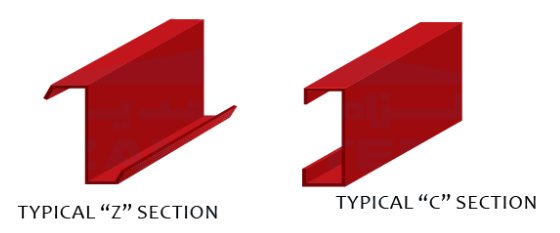

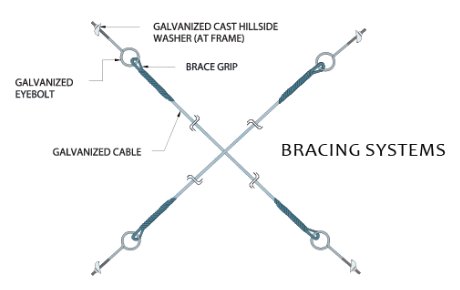

2. Secondary Framing (Bracing, Z and C section purlin)

Purlin, tie bar and bracing are secondary structural members used to support the wall and roof cladding. Secondary members as purlin, tie bar, column bracing and horizontal bracing connect the main frame and help in resisting part of the longitudinal loads that are applied on the building such as wind and earthquake loads. Steel purlin is available in high grade steel conforming to GB/T 2518-2008, Q235B/Q345B Grade or equivalent, available in 1.8 mm. 2.0 mm, 2.2 mm, 2.5 mm and 3.0 mm thickness. The purlin come with a galvanized sheet. Column bracing is a connecting member set between two adjacent columns to ensure the overall stability of the building structure, improve lateral stiffness and transfer longitudinal horizontal force. Column bracing will be round steel or angle steel according to the building need.

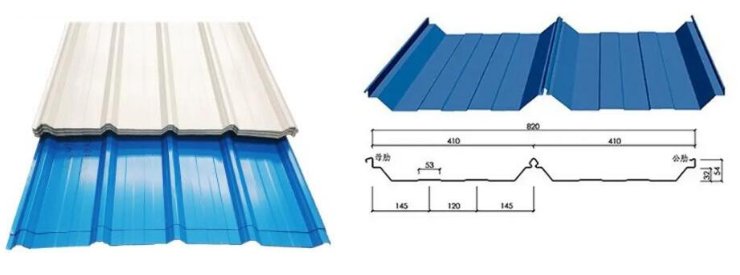

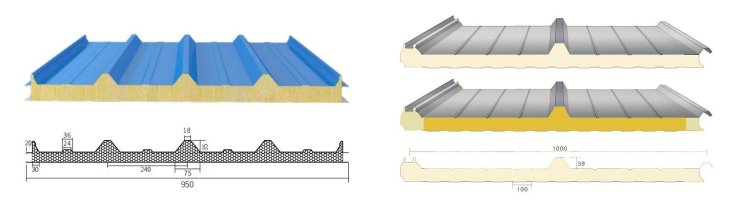

3.Roof and wall cladding system

We offer a complete line of Roof and wall steel sheet, sandwich panel, and their related accessories, steel cover, trims, eave gutter, curved eave cover, wall flashing for a wide range of building applications. Variety of profiles, base metal, metal substrates and coatings for its sheet. The metal sheet are used as roof and wall panels, interior roof and partition panel, etc. Steel sheet, its base sheet is usually be galvanized sheet or aluminium zinc sheet with organic coating. It has the advantages of good corrosion resistance, bright color, beautiful appearance, convenient processing and forming, and has the original strength of the steel plate and low cost. The thickness of steel sheet usually be 0.3mm-0.7mm and used in different building and requirement. Sandwich panel is composite insulation panel made by two sides steel sheet and heat insulated core material through binder (or foam). The core can be EPS (polystyrene ), fiberglass wool, rock glass wool and PU (polyurethane), thickness 50mm, 60mm, 75mm, 100mm, 150mm, 200mm, etc.

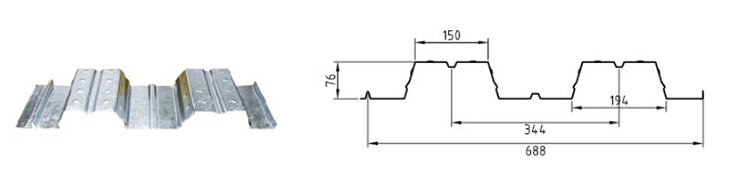

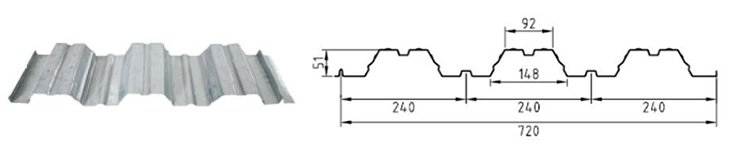

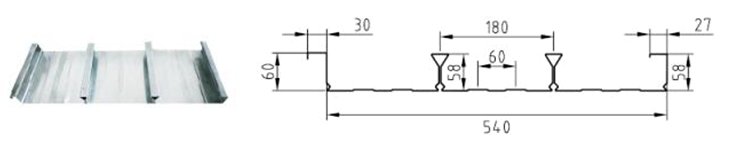

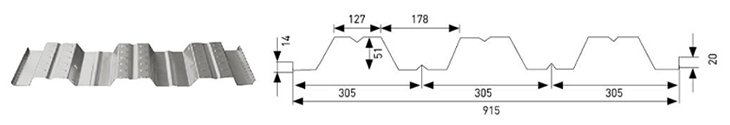

4. Steel Decking Floor

The pressed steel plates supporting the floor concrete are called profiled plates, also called floor bearing board. The steel decking board are widely used in multi-storey buildings such as power plant, exhibition hall, steel structure workshop, cement warehouse, steel structure office, airport terminal, railway station, stadium, concert hall, grand theater, large supermarket, logistics center, Olympic venues and sports venues and other steel structure buildings. It can adapt to the main steel structure rapid construction requirements, can provide a firm platform in a short time, and can take flow repetitive construction operation, laid a number of floors decking board, and pouring concrete slab.

AutoCAD, PKPM, MTS, 3D3S, Tarch,Tekla Structures(Xsteel)V12.0.etc

Quality check & control

Production Processing & Shipping